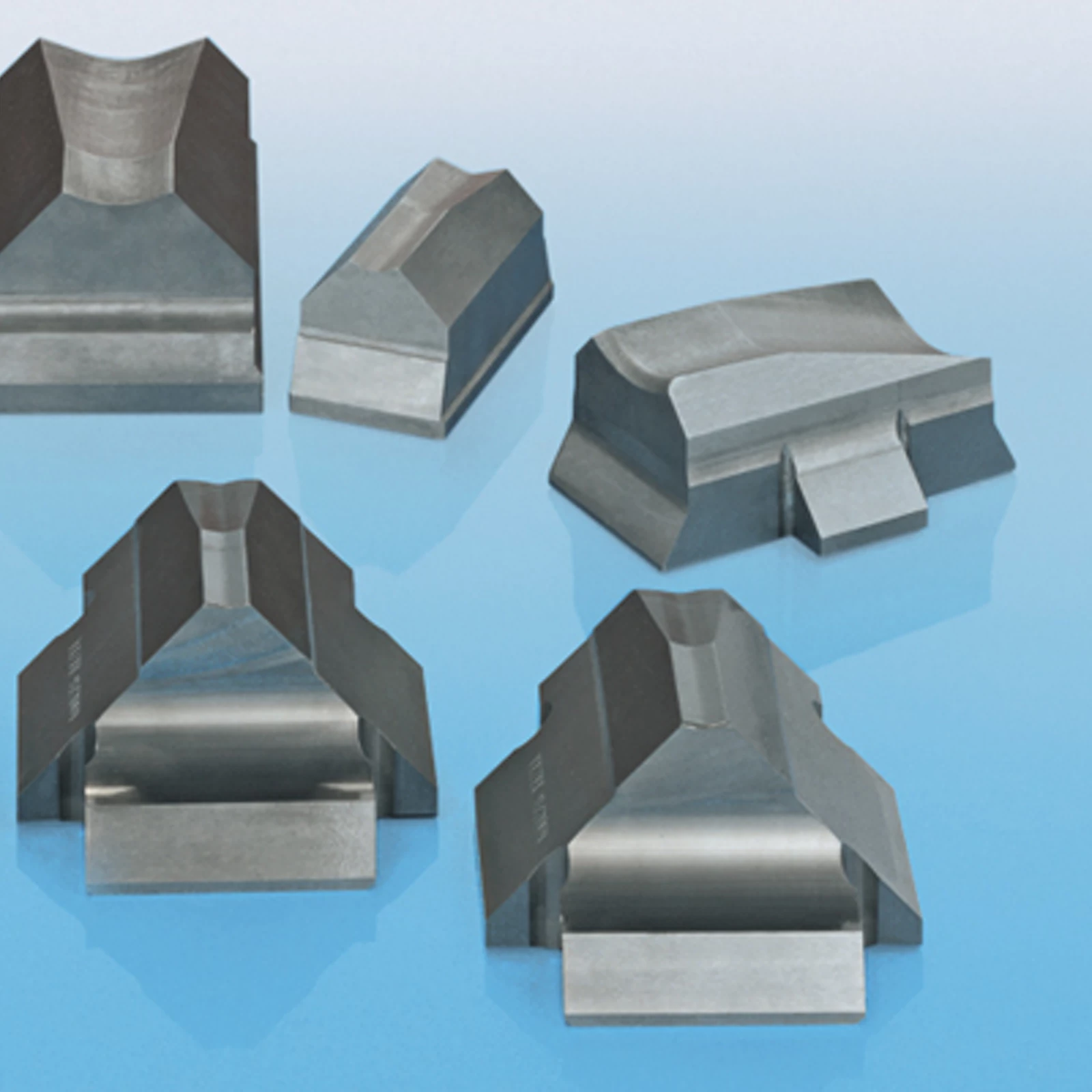

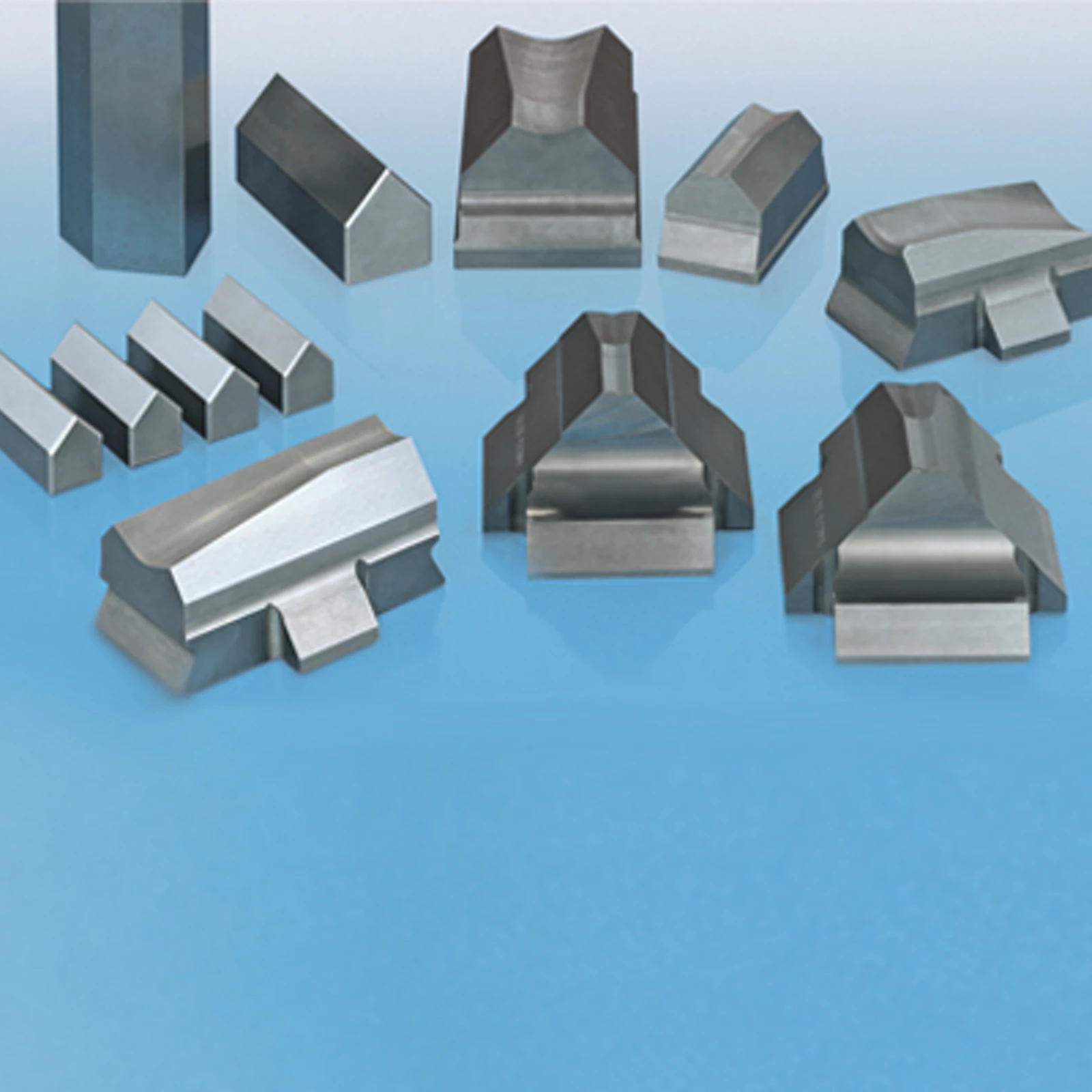

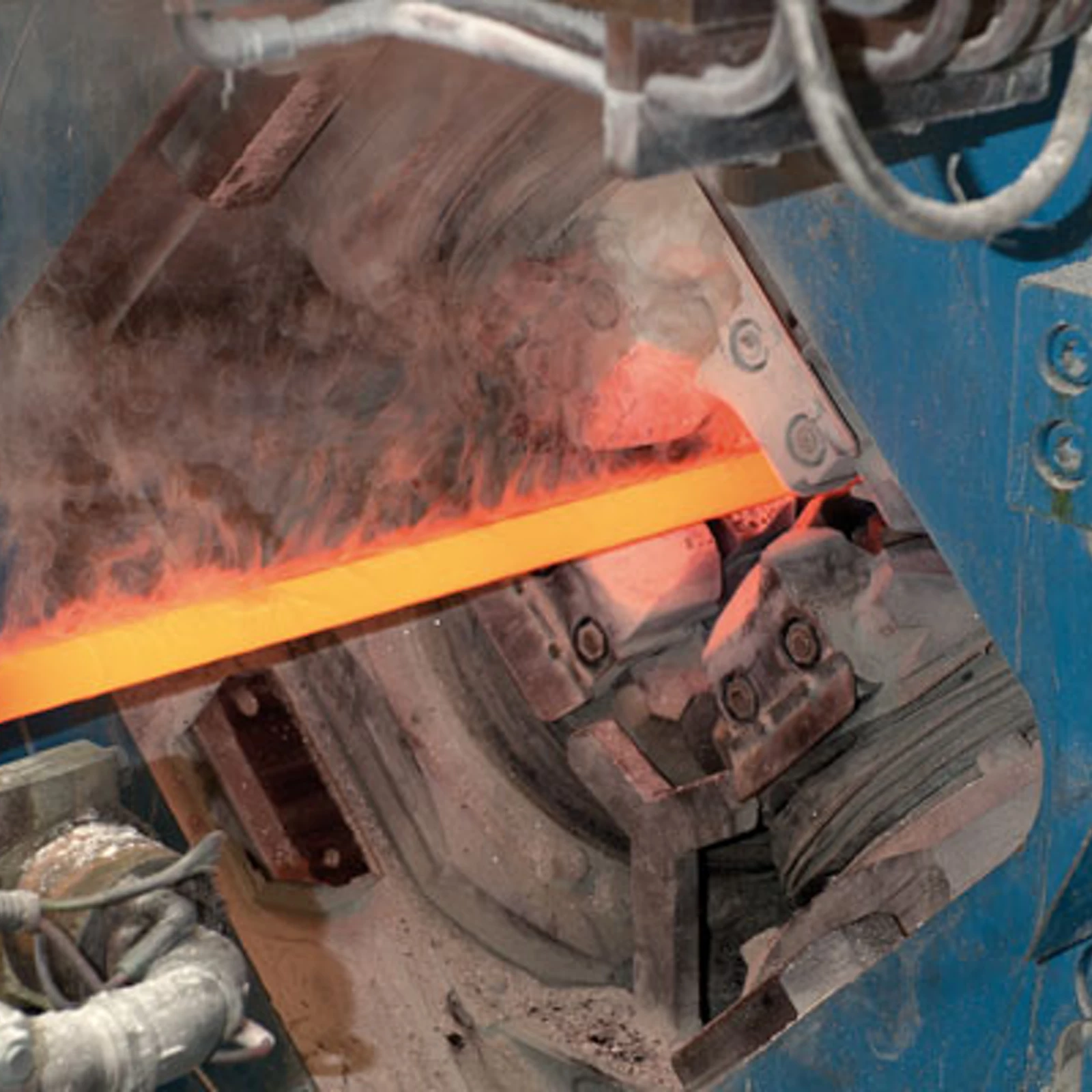

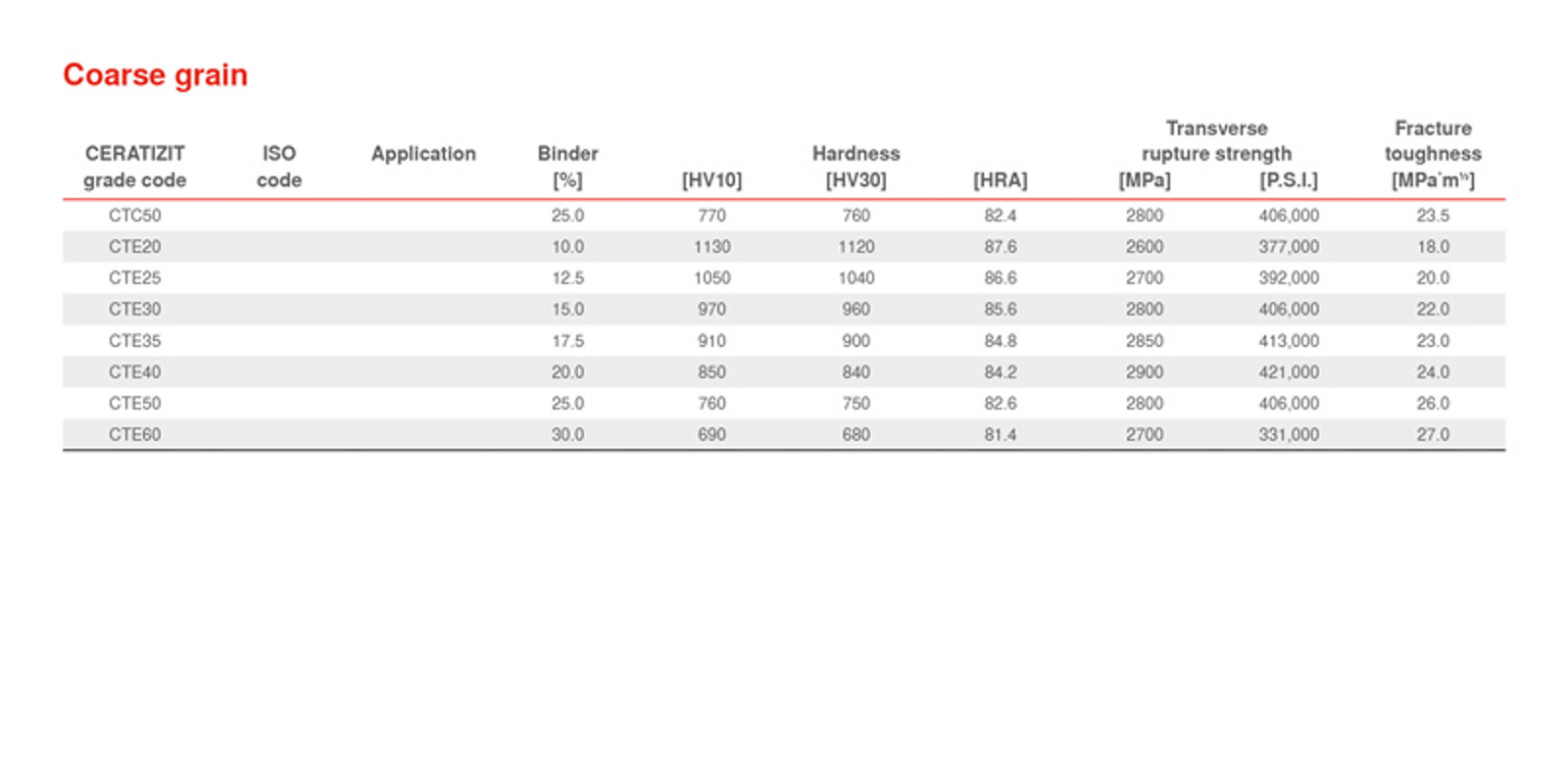

Powerful under extreme conditions

Resilient to the limit

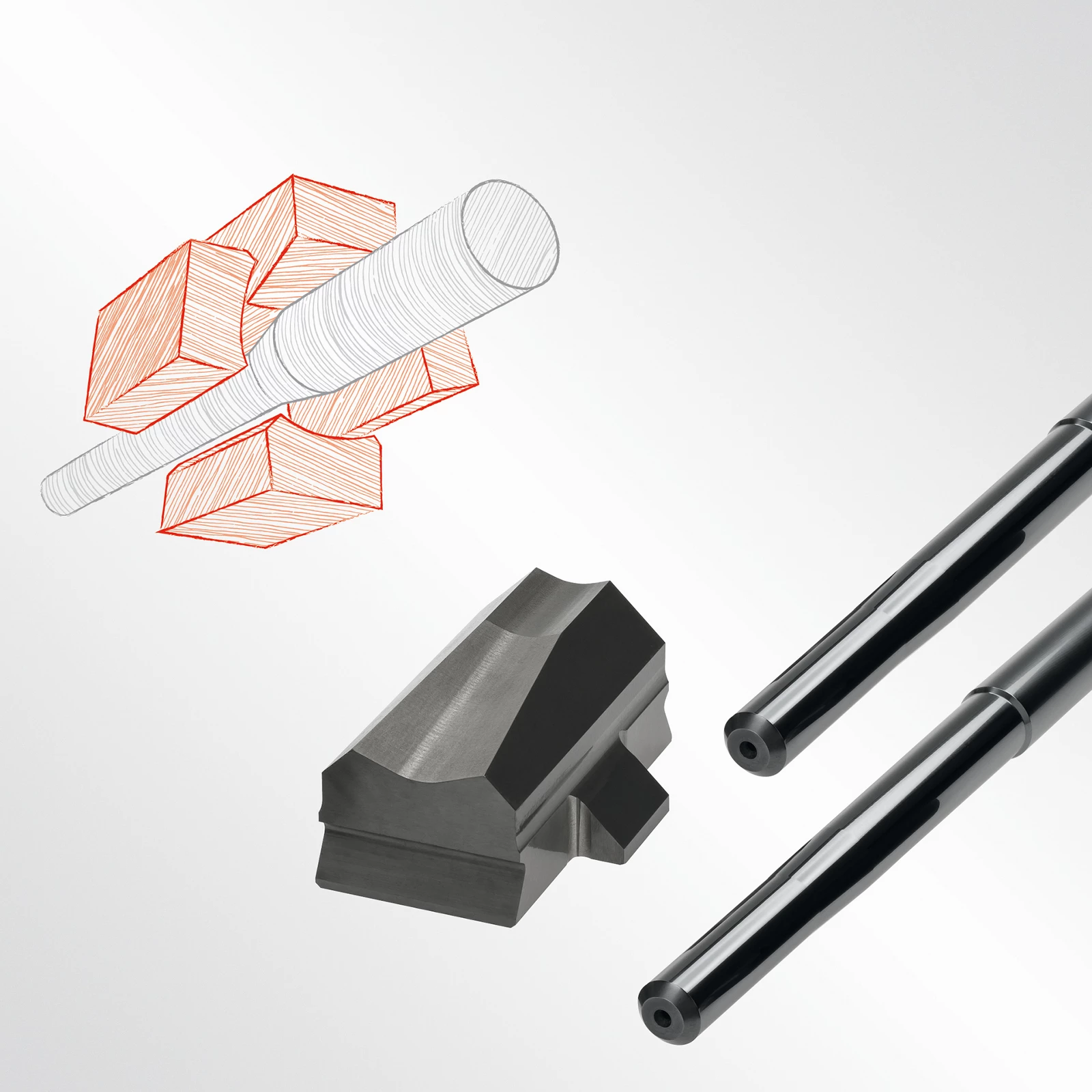

Thanks to special coarse grades, our forging tools withstand high pressures and extreme heat. They resist every kind of abrasion and wear and achieve a long tool life.

Repeatedly high-grade forging

Due to the powder metallurgical properties, the tools achieve consistent quality and forging processes on the work piece.