June 22, 2022

CERATIZIT introduces innovative carbide grades for cold and hot metal forming

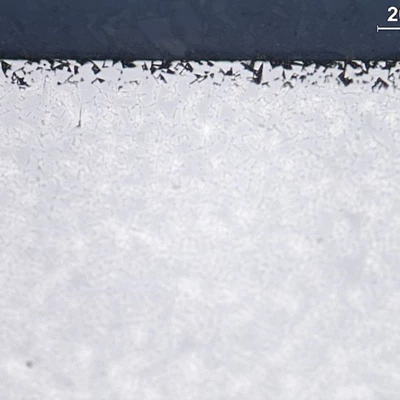

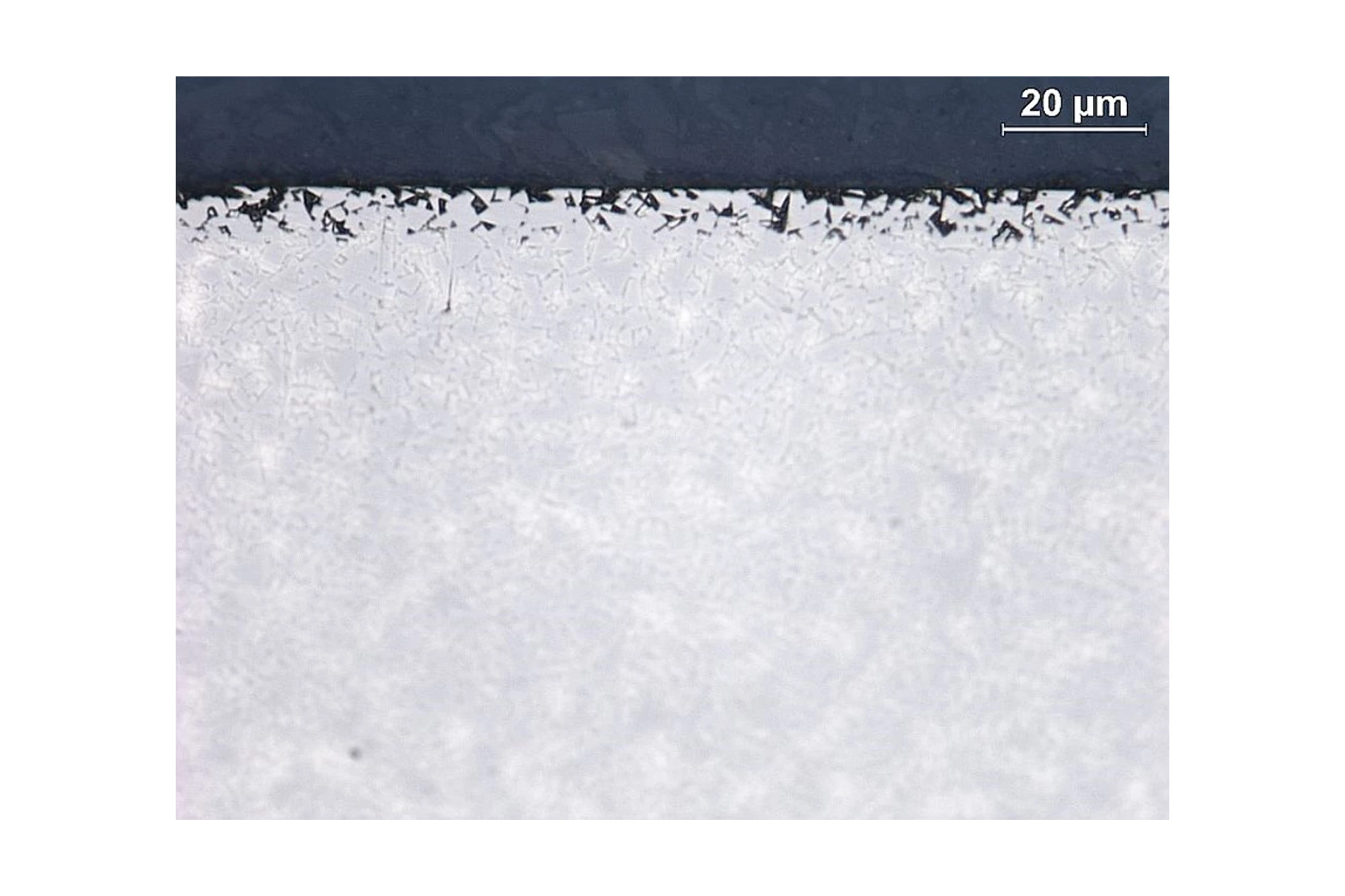

CFG-CTM30 shows a much lower corrosion depth after polarisation test in pH5.

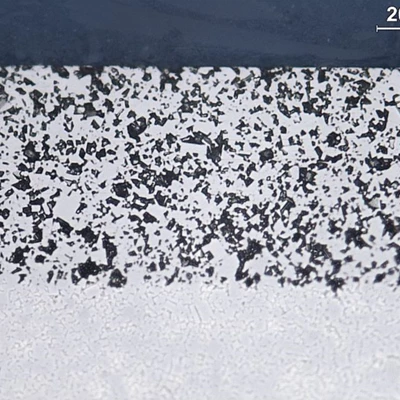

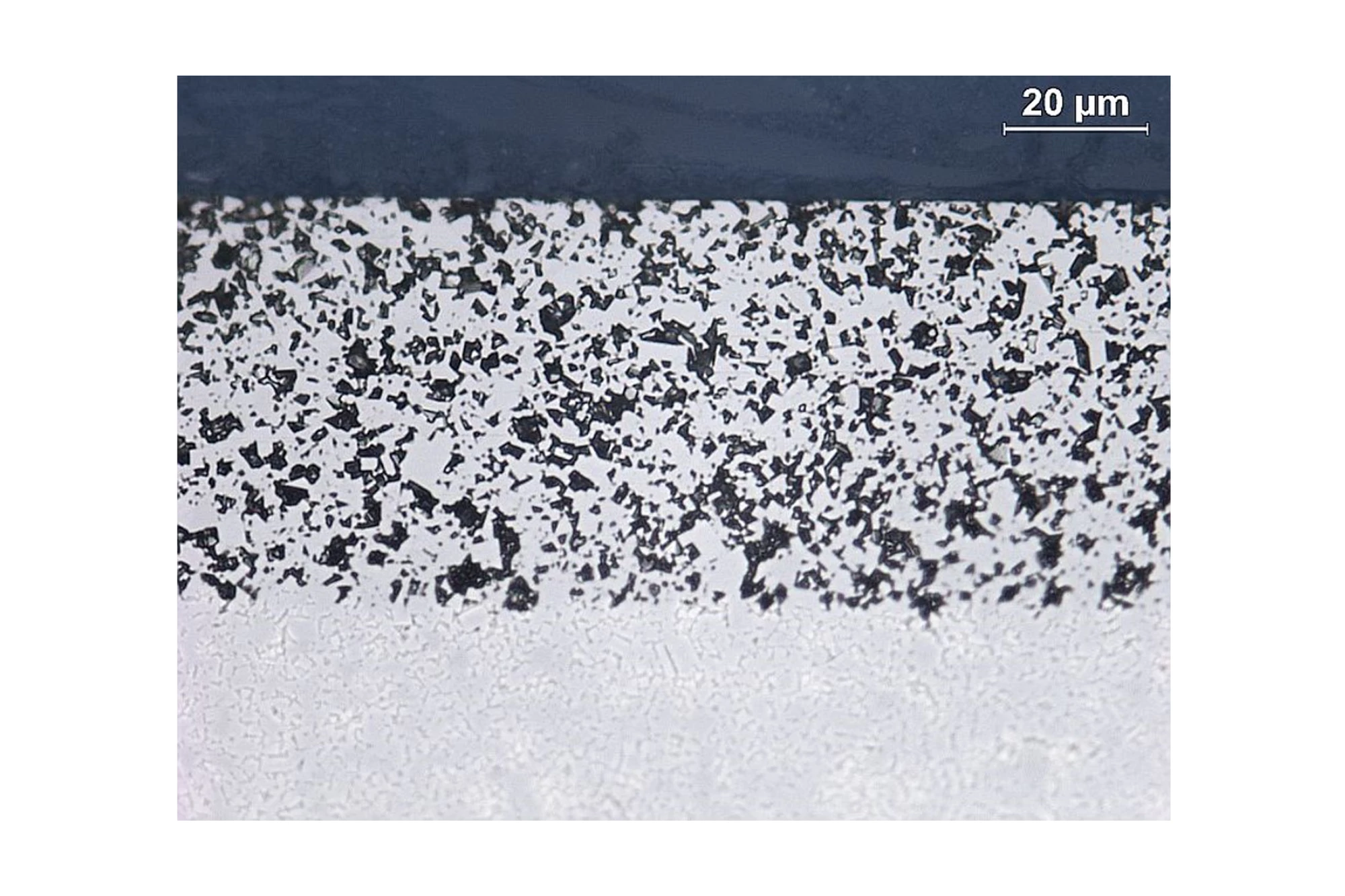

Corrosion depth of a conventional tungsten carbide grade after polarisation test in pH5.

CERATIZIT S.A., Mamer, Luxembourg (headquarters), June 22, 2022

On the occasion of Wire and Tube 2022 in Düsseldorf, hard material specialist CERATIZIT is presenting the new CFG series of tungsten carbide grades that have been specially developed for cold and hot metal forming processes. The three CFG grades are characterised by an outstanding resistance to corrosion, oxidation and adhesion.

The new CFG grades cover a wide range of mechanical properties and thus applications. From standard cold forming stamping processes to high impact and thermal shock applications. Their optimised characteristics result from an innovative carburisation process. In addition to hardness and toughness, their resistance to both corrosion and oxidation as well as adhesion is vital when it comes to the tool’s performance. To round it off, an innovative binder composition – combined with excellent resistance to thermal shock – makes them usable for hot and cold forming applications.

Record-breaking durability

This combination of properties means that the new varieties do not simply work but score higher than conventional tungsten carbide grades in a core criterion for any metal forming tool: maximum tool life. “Many CFG solutions have already proven to have a significantly longer service life compared to tools made from conventional tungsten carbide materials. Our experts will be happy to discuss the right grade for your application at any time, “ said Romain Steckler and Antonello Valsecchi, Segment Account Managers for Metal Forming.

In addition to the new CFG grades, the CERATIZIT team will be exhibiting a wide range of products at stand C53 in hall 9 at Wire and Tube 2022. The exhibited portfolio includes solutions for bar peeling, the oil and gas industry as well as wire and tube processing.

More information on the CFG grades is available under www.ceratizit.com/int/en/search.html?query=CFG&filter=all.

Downloads

- Corrosion depth of a conventional tungsten carbide grade after polarisation test in pH5.DOWNLOAD IMAGE (213.5 kB)

- CFG-CTM30 shows a much lower corrosion depth after polarisation test in pH5.DOWNLOAD IMAGE (113.6 kB)

Press contact:

CERATIZIT – with passion and a pioneering spirit for hard materials

For over 100 years, CERATIZIT has been a pioneer in developing exceptional hard material solutions for machining and wear protection. The private company, with registered offices in Mamer, Luxembourg, develops and produces highly specialised cutting tools, indexable inserts, rods made from hard materials and wear parts. The CERATIZIT Group is the global market leader in various application segments and successfully develops new carbide, cermet and ceramic grades, such as for wood and stone working.

With 7,000 employees at 30 production facilities and a sales network with over 50 branches, CERATIZIT is a global player in the carbide industry. The company's international network includes subsidiary Stadler Metalle and joint venture CB-CERATIZIT.

The technology leader is continually investing in research and development and holds 1,000 patents. Innovative hard material solutions from CERATIZIT are used in various sectors, including mechanical engineering and toolmaking, in the automotive and aerospace industries and in the oil, gas and medical industries.