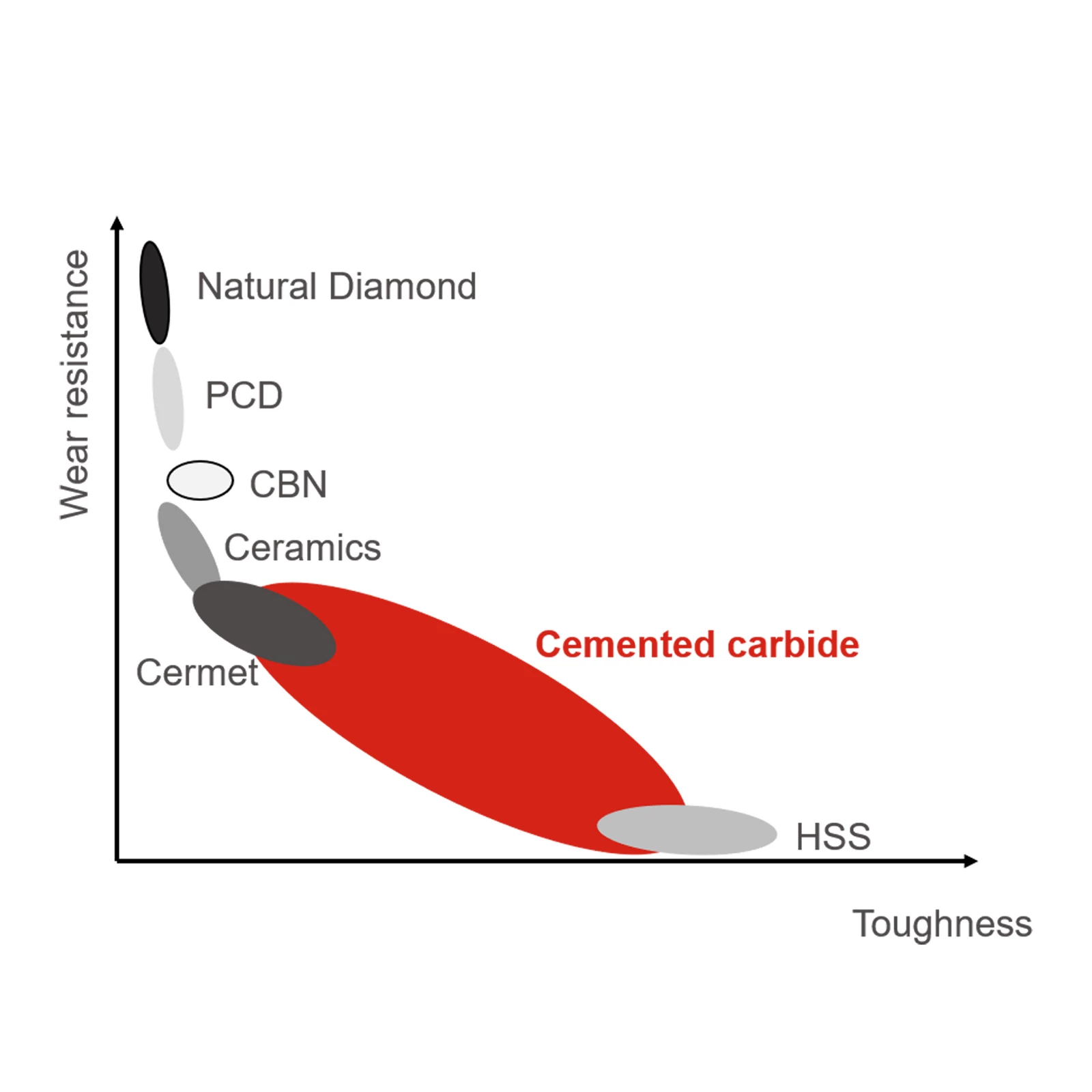

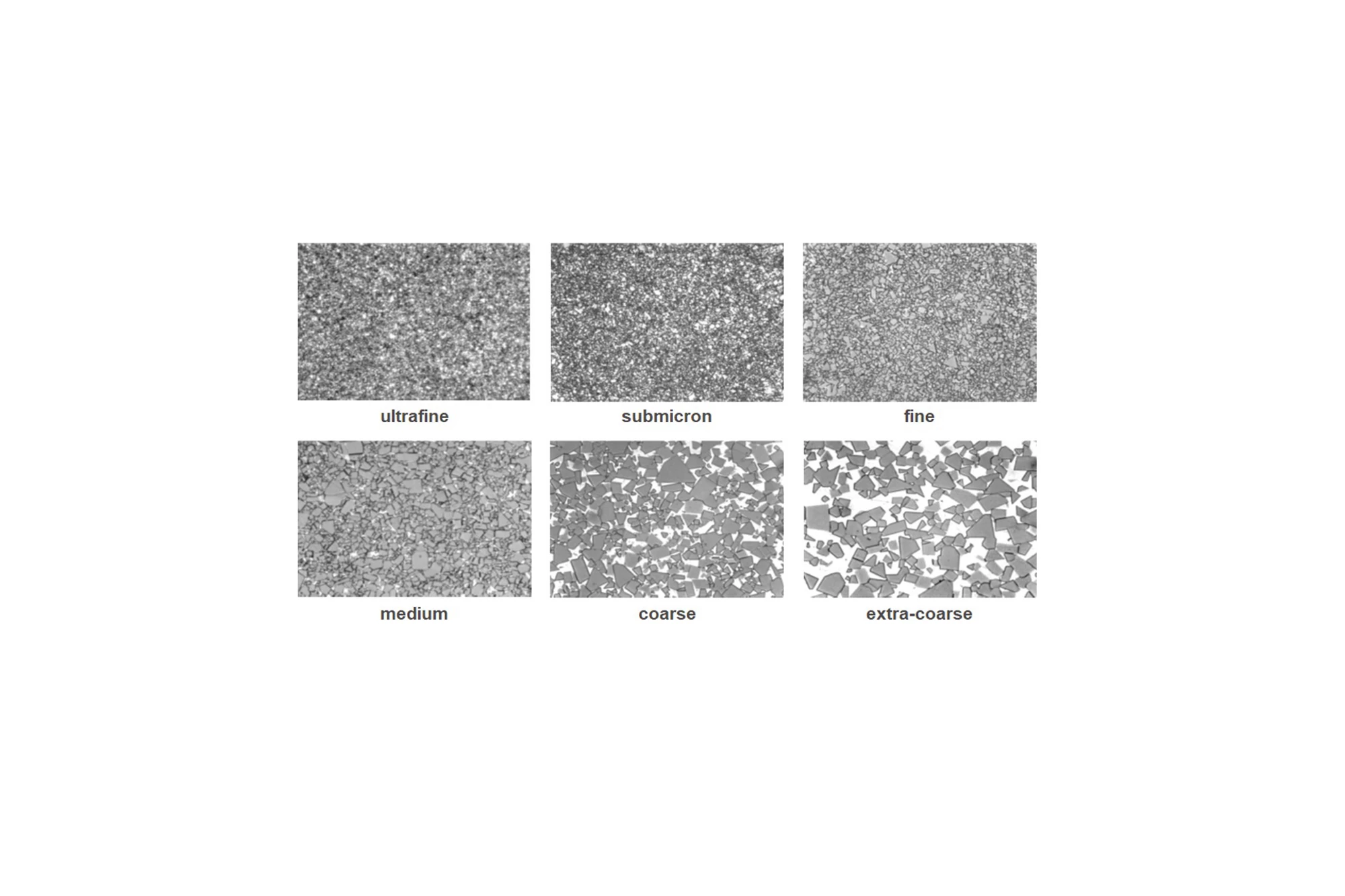

There is a wide range of extremely wear-resistant carbide products which include an equally wide range of different components for a variety of industries. In wood and stone working, cemented carbide is used, for instance, in the form of saw tips for circular saws and drill bits for drilling all metal alloys. The automotive industry uses wear-resistant carbide components for Common Rail Systems. In the oil and gas industry, carbide components minimise the downtime in pipelines and in exploration drilling operations.

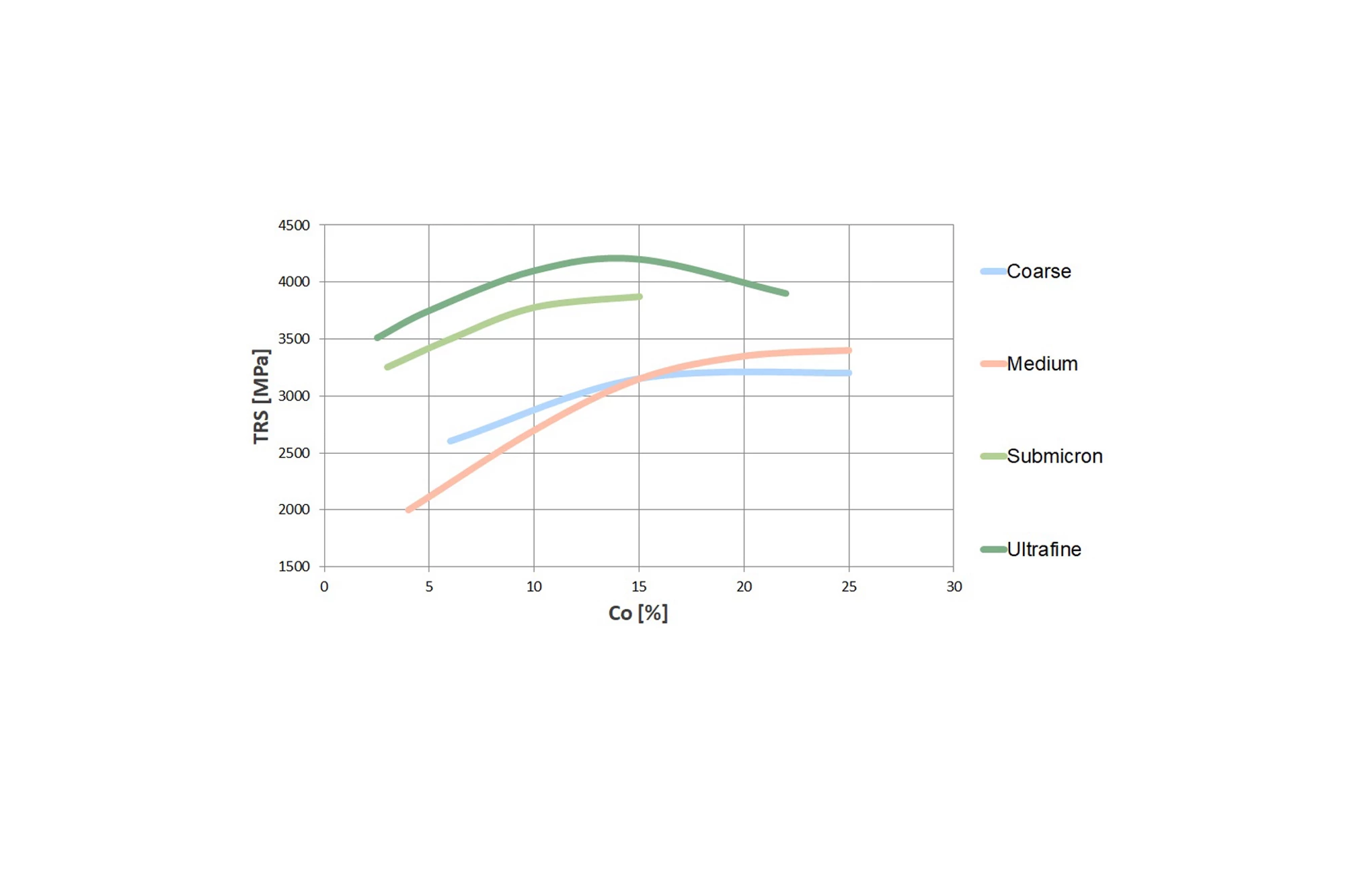

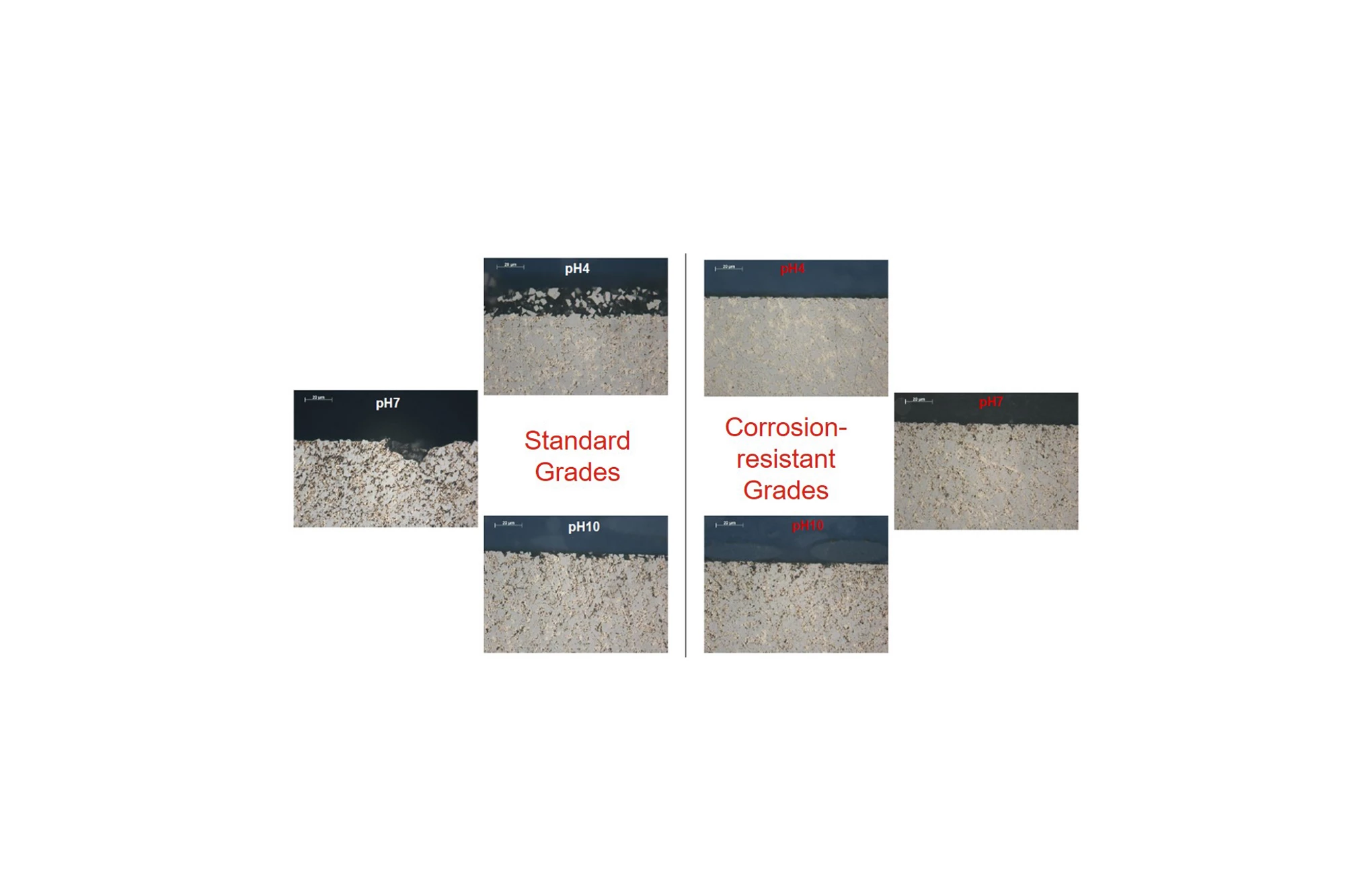

Whether stamping, bending, blanking, metal forming, powder pressing or fine cutting – with our active parts made of carbide, you can achieve high output rates and quantities, enabling you to turn out mass-produced parts economically. This is ensured by the optimised edge stability of products for blanking and lamination tools as well as by their reliability and process stability and better tensile strength combined with reduced tendency to and speed of corrosion.

Scratchproof watch cases, components for metal forming and tool making, water-jet nozzles, sputter targets for the production of diamond-like carbon coatings (DLC), high-pressure tools for the production of synthetic diamonds or blanks for hob milling cutters or rotary cutter blanks are also manufactured today from cemented carbide. Special grades approved by the US Food and Drug Administration are even used for medical systems and in the food industry.